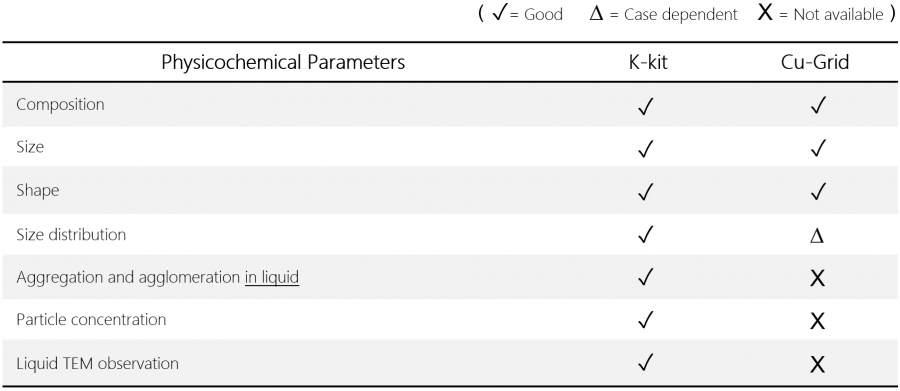

| MA-tek's enabling solution for liquid analysis by TEM Why K-kit

| |

| Examples of K-kit Application | |

| K-kit is an innovative wet cell which simple, fast, reliable, powerful and affordable for use, perfectly meeting the surging demands on liquid-EM analysis for both industry and academia. | |

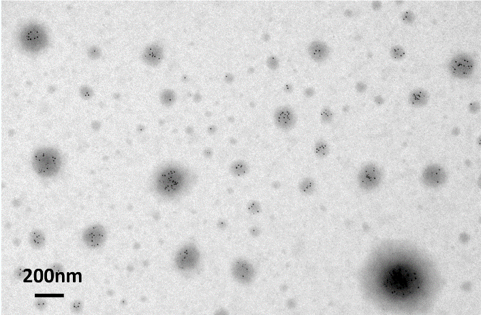

NOAAs of abrasives in CMP slurry | |

.jpg) |  |

K-kit can be used for characterizing the primary and secondary particles in undiluted CMP slurry. | |

Nanomaterials & Chemicals | ||

.PNG) |  | .PNG) |

Carbon nanotubes (WMCNT) in Water | Al2O3 nanoparticles in NMP solution | Pigment nanoparticles of printer ink |

Biologcal specimens & Nanopharmaceuticals | ||

|  |  |

The nucleoid of E.coli | Collagen bundles in liquid | Extracellular vesicles of platelets |

.PNG) |  | .PNG) |

Abraxane® drugs (paclitaxel) in saline | AuroVist® gold nanoparticles in PBS | Liposomes with negative staining |

Foods & Cosmetics | ||

|  |  |

Snail mucins in essence | Calcium particles in milk | Nano-additives in beer |

.PNG)

| | ||

| .PNG) | |

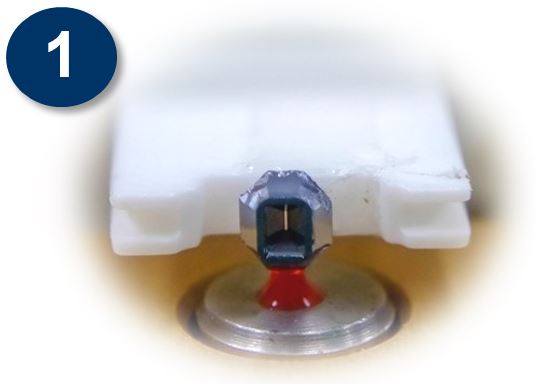

K-kit is carried with a 3mm TEM grid so that it is compatible with all kinds of TEM holders. | ||

.PNG)

| | ||||

| | | |||

|  | |||

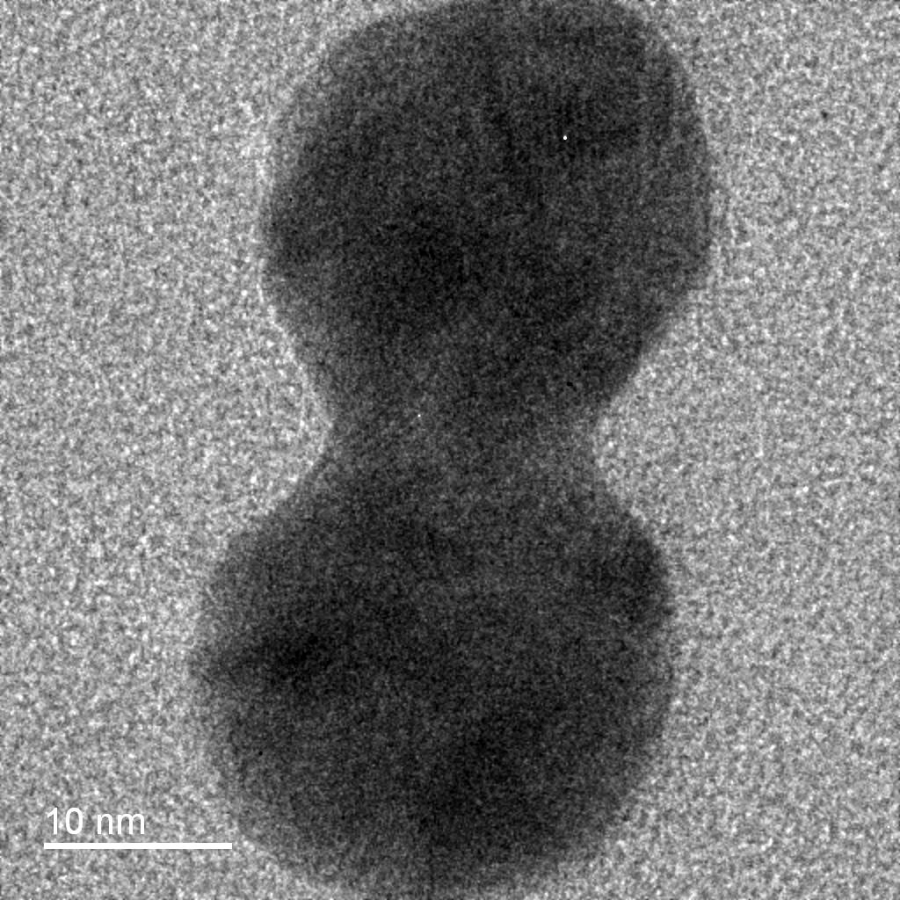

| TEM image of liquid state CMP slurry with K-Kit, enabling individual particles to be clearly identified. | TEM image of dried CMP slurry on Cu grid, unable to be analyzed individual particles due to agglomeration. | |||

| ||||

.PNG)

| | |

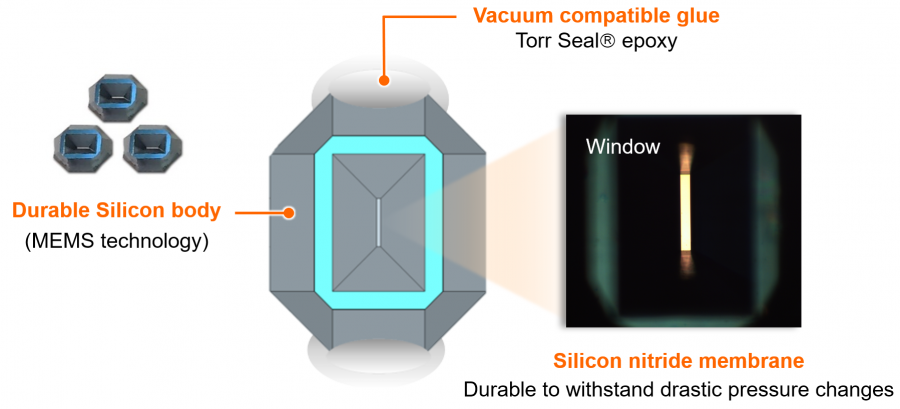

| K-kits are Si-based microchannel devices with silicon nitride windows that allow TEM observation. The seemingly irregular shape is a result of KOH anisotropic wet etching, which is also responsible for forming the rectangular observation window in the middle of the device. The liquid channel is parallel to the window, with openings at both ends. |

| Broad temperature range for K-Kit -196°C to 120°C (Applicable with heating & cryo TEM holders) | |

| |

| .PNG) | |

Channel tips There are channel tips at both ends, to protect the surface condition and cleanness of the channel in K-kit. | ||

| ||

| Reliable liquid loading By capillary action, liquid can be loaded in a K-kit reliably, even the viscosity of it up to 3,000 mPa-s. | Unibody structure Cross-contamination free (Disposable), no need to do further assembly, surface treatment or pre-cleaning process before the use. |

| | ||

| Good resistance to solvents After soaking the K-kit sealing glues (Torr Seal) in those chemicals individually for 24 hours, the FTIR analysis results looked perfect. | ||

|  | |

.PNG)

| | |

|  |

| | |

|  |  |

| (Example) As shown in the TEM images of gold nanoparticles that formed from reduction process of AuCl4 solution, the lattice lines of gold particles could be clearly observed by using Gap0.2um/ SiN30nm K-kit. (By FEI Talos TEM @ 200KV) | ||

|  |

| (Example) TEM images of multi-walled carbon nanotubes (WMCNT) that were fully dispersed in water. By using Gap2um/ SiN30nm K-kit, the structures of MWCNTs could be observed clearly. (By Hitachi HT7700 TEM @100KV; WMCNTs: OD 30-80 nm, Length <10 μm, 10wt%) | |

.PNG)

| | |||

|  |  | |

| The loaded liquid sample is sealed and imaged using TEM in the native liquid environment. (Acceptable image quality with liquid inside the K-kit) | |||

|  |  | |

| A patented liquid drying protocol preserves the original morphology and physical state of nanomaterials with improved imaging resolution. (Very good image quality, due the the channel being dried out) | |||

| |

| | ||

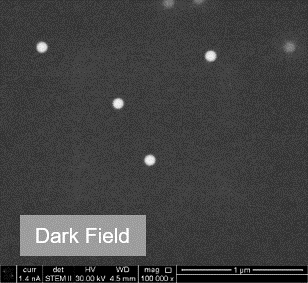

| SEM observation K-kit also can be imaged by SEM, no matter what it prepared in wet or dried mode. Per our test results, the particles (Au) in K-kit with sizes less than 10nm could be well imaged by using SEM/ STEM. | ||

.png) .png) |   | |

| Gold nanoparticles in K-kit | 100nm NIST Polystyrene beads in K-kit | |

| | |

Multiple loadings With an unibody structure, K-kit can be used on multiple-loading applications, e.g. immunoelectron microscopy or catalyst chemistry studies etc. |

| |  | |  | |  |

1st K-kit loading with liquid A | Prepared in dry mode for liquid A | 2nd K-kit loading with liquid B | Prepared in dry or wet mode again for liquid B |

| (Example) The presence of specific platelet granules could be labelled and observed by using a K-kit with multiple loadings. After some necessary pre-treatments and washings, the platelet sample in K-kit was incubated with the primary antibody (mouse monoclonal anti-P-selectin antibody) and next was reacted with a secondary antibody (6-nm gold-conjugated goat anti-mouse IgG antibody) for 2h at 37°C, and then the K-kit was sealed and examined in TEM. (Appl. Sci. 2020, 10, 4946) | |

|  |

| Immunoelectron micrographs of isolated platelet granules in a K-kit. | |

| | ||

| Negative Staining Some biological granules such as liposomes or exosomes usually suffer low-contrast issue in their EM images; negative staining with heavy elements (metals) can enhance the contrast for those samples. Regarding the negative staining protocol for K-kit, we suggest using Uranyl Acetate (UA). Please refer to the steps as below, (1) Dilute the UA agent first by adding exact DI water, to make it the volume ratio of 2% UA in the liquid. (2) Mix the diluted UA and the sample solution, by the volume ratio of 1:1 (3) Liquid loading with K-kit and TEM observation | ||

|  |  |

| On Cu grid (In dry state) | In K-kit (With liquid) | |

(Example) Negative staining TEM images of collagen on Cu grid and in K-kit. As shown in Fig. B, the collagen nanofibers could be clearly observed by using a wet-mode K-kit. | ||

|  |

| Negative staining TEM images of isolated platelet granules in K-kit. (Appl. Sci. 2020, 10, 4946) | |

| | |

| EDX Analysis In a TEM, an EDX detector is usually located at an angle of around 10 - 20º with regard to the sample; X-ray signals excited from the observation window of a K-kit will be easily blocked by that deep cavity. If so, by pointing the window long side of the K-kit toward the EDX detector along with tilting the TEM holder at some angles over 15º, which can make the EDX analysis achievable on it. | |

|  |

| |

| | ||

Diffraction Pattern Analysis TEM diffraction patterns of nanoparticles in liquid can be analyzed by using K-kit. | ||

|  |  |

| NBD (Nano-beam diffraction) | SAD (Selective area diffraction) | |

| In this example above, Au nanoparticles were formed from reduction process with AuCl4 solution and analyzed with FEI Tecnai TEM @200KV. | ||

.PNG)

| | ||

K-kit can be the most fastest and convenient option in the market for liquid-TEM observation. | ||

| Around 90min required for 10 samples Liquid loading and gluing for 10 K-kits (~70min) + vacuum pumping (~20min) | |

| 450min at least for 10 samples One by one; it needs the steps including surface treatment, assembly, leakage detection, and post-clean etc. for one sample. (> 45min for each) | |

|

.PNG)

| |  |

| K-kit brochures & teaching videos are available for downloading below. | |

| | |

| | |

| | |

| | |